NBR

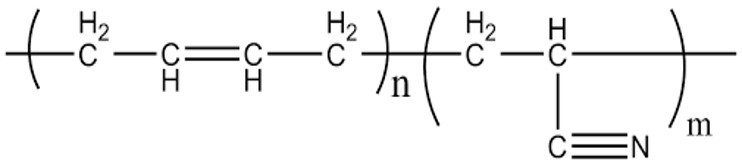

Nitrile rubber is prepared by emulsion polymerization of butadiene and acrylonitrile. It has excellent oil resistance, high wear resistance, good heat resistance and strong adhesion. The disadvantages are poor low temperature resistance, poor ozone resistance, poor insulation performance and slightly lower elasticity. Nitrile rubber is mainly used in the manufacture of oil resistant rubber products. Referred to as NBR, a synthetic rubber prepared by copolymerization of butadiene and acrylonitrile. It is a synthetic rubber with good resistance to oil (especially alkane oil) and good aging resistance. The more acrylonitrile content, the better the oil resistance, but the cold resistance is correspondingly reduced. It can be used for a long time in air at 120 ° C or in oil at 150 ° C. In addition, it has good water resistance, air tightness and excellent bonding properties. Widely used in the manufacture of various oil-resistant rubber products, a variety of oil-resistant gaskets, gaskets, casings, flexible packaging, soft rubber hoses, printing and dyeing rubber rollers, cable rubber materials, etc., in the automotive, aviation, petroleum, copying and other industries become essential Elastic material

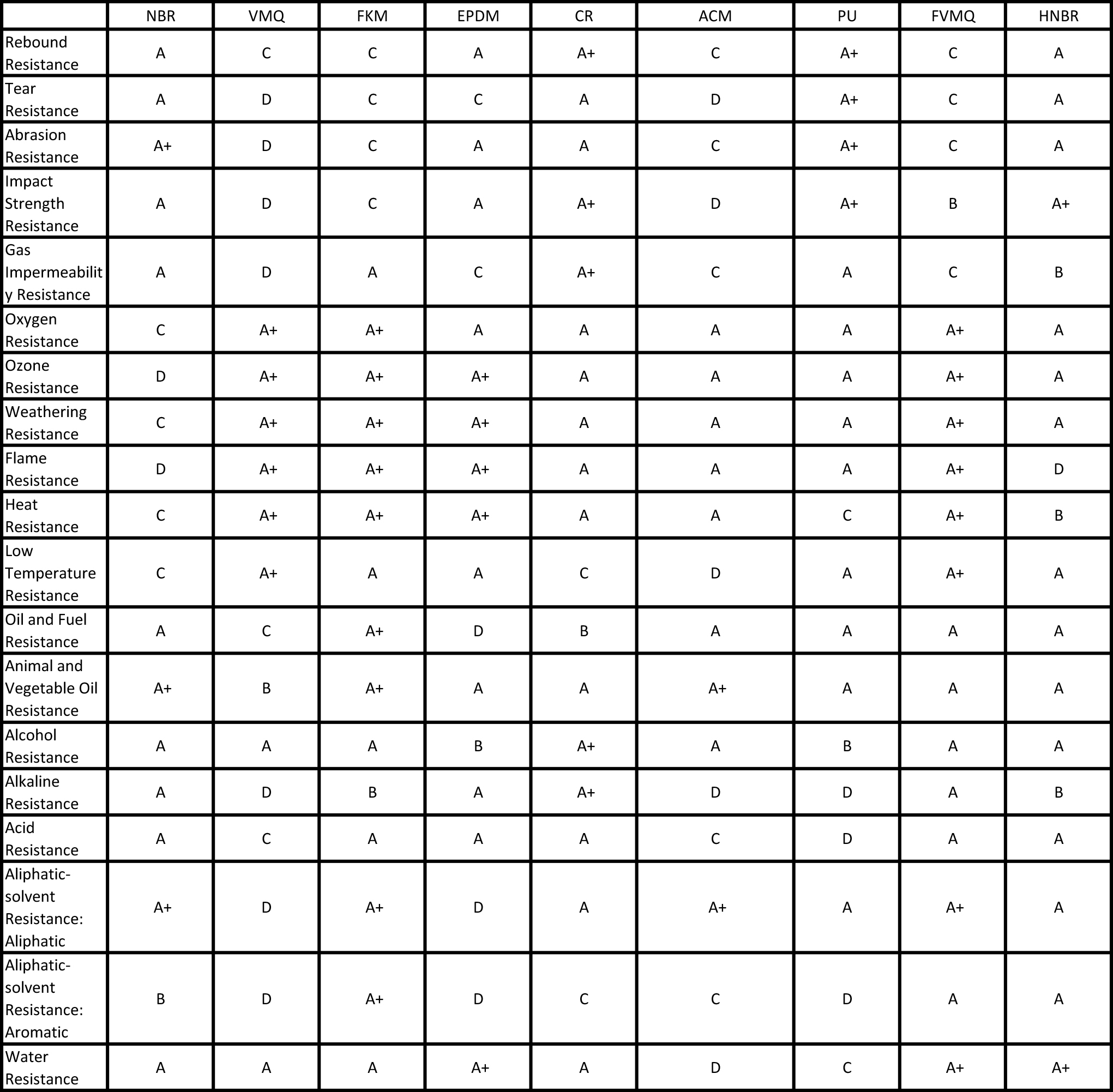

STANDARD COMPOUND LIST

Feedback list