Products & Materials

- .Proprietary Materials

- .Water Handling Application

- .Food Processing

- .Gas Supply System

- .Chemical Resistance

- .Standard FKM Compounds with Low Compression Set

- .Product Development

- .Engineering & Co-Design

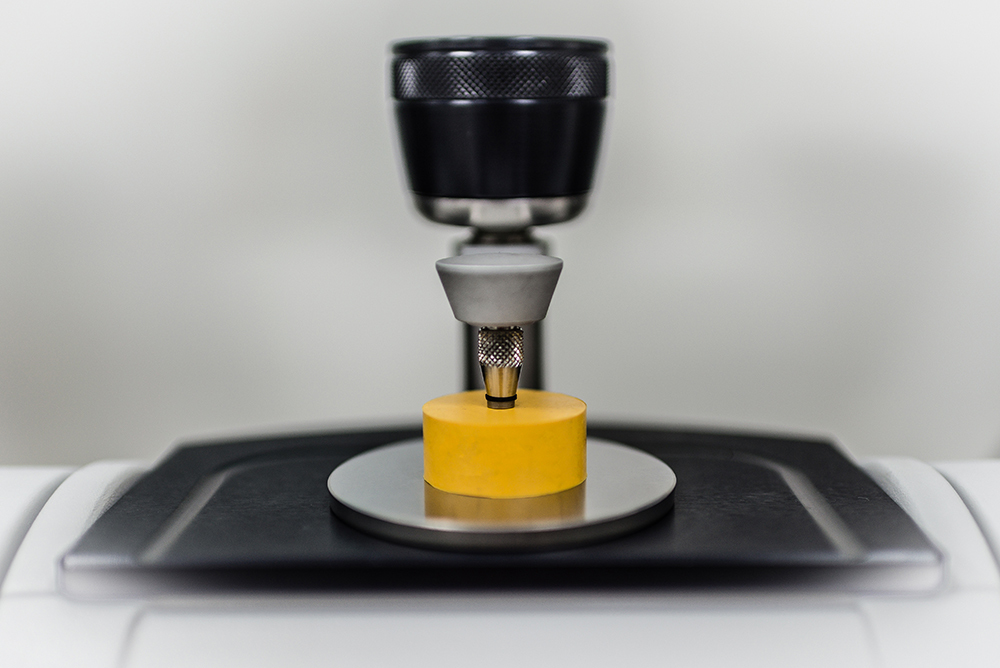

- .O-Ring with strict Tolerance

- .Elastomer Combination Seals

- .Integrated Rubber-to-Metal Bonding Seals

- . PTFE-Coated Seals

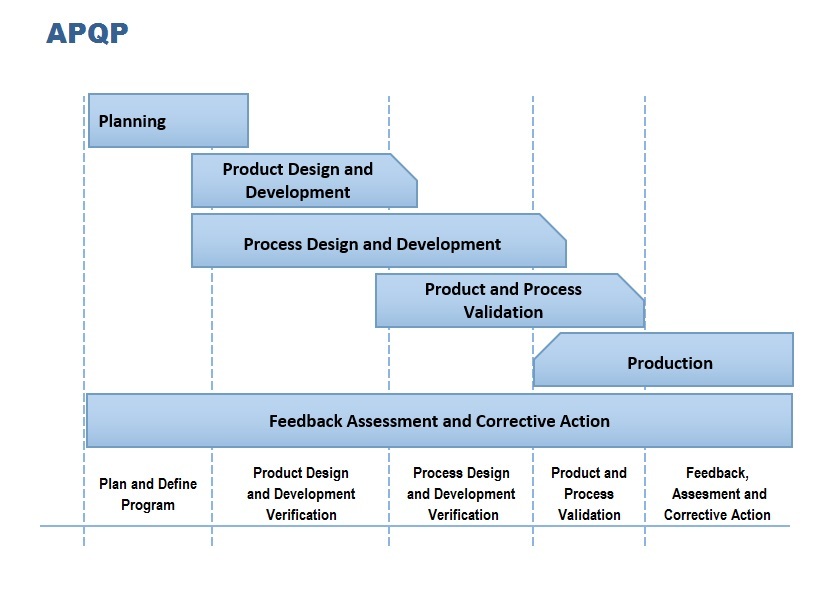

APQP

- .CFT (Cross Functional Team)

- .Feasibility Study

- .Determining Customer Specific Requirements

- .Up-front Quality Planning

- .Process Design and Development Verification

- .Process Validation and Production Feedback

- .Launch, Assessment & Corrective Action

- .Continuous Improvement

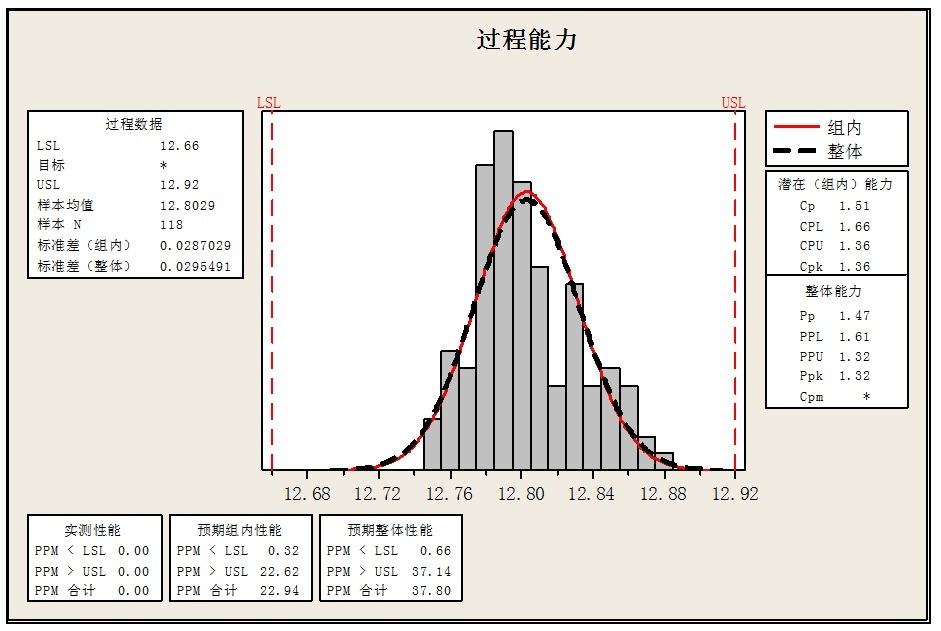

Quality Control

- .Six Sigma

- .Control Plan

- .Inspection Planning

- .Tools, Fixtures and Equipment

- .Capability Study

- .Logistics

- .Planning of Packaging & Labeling

- .Corrosion, Deformation Prevention, Cleanliness

- .Material Flow

- .Traceability

Capacity & Qualification

- .Manufacturing Prototypes (Prototyping)

- .Product & Process Development Release

- .Qualification of Special Process

- .PPAP (Production Part Approval Process)

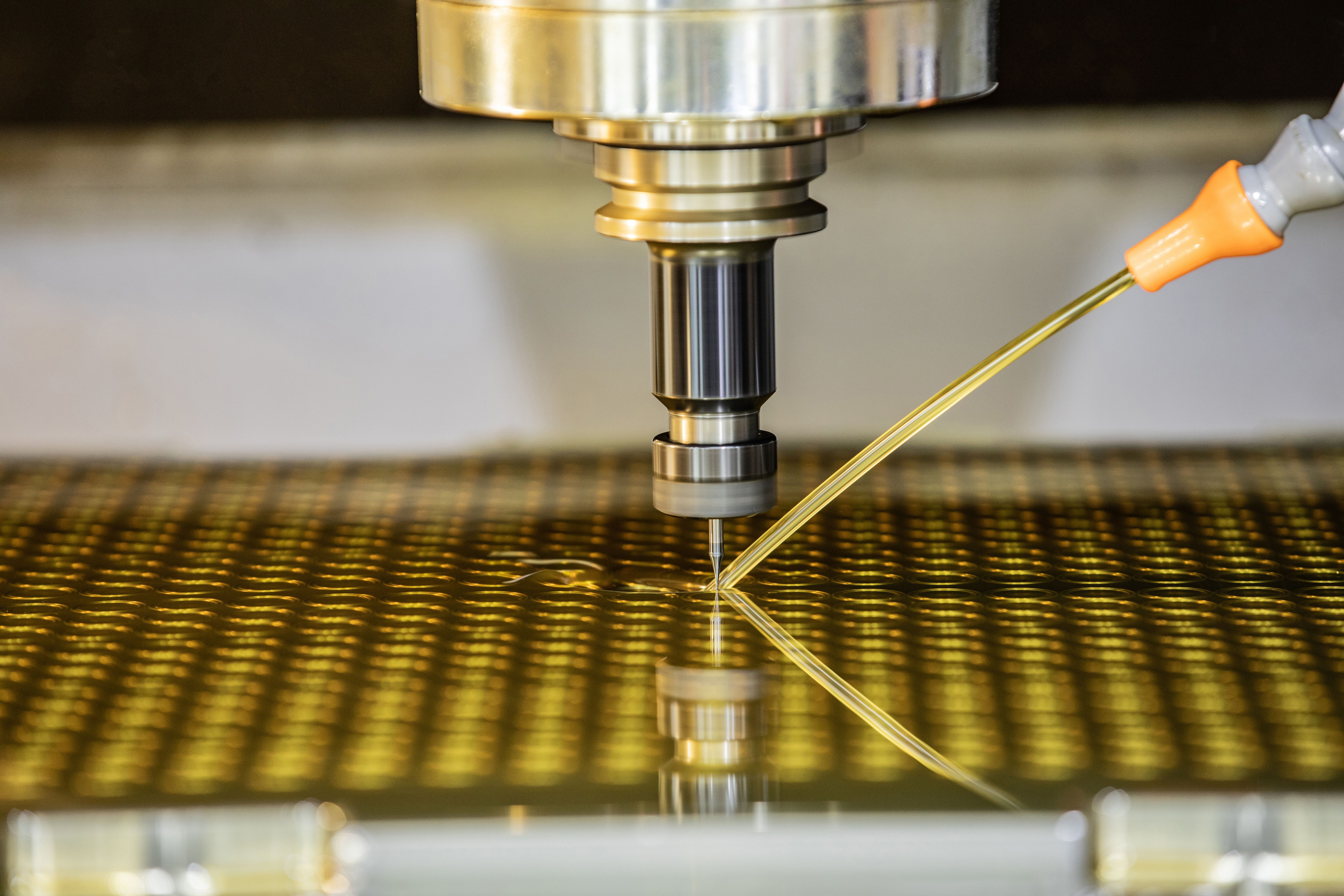

Facilities & Equipments

- .CNC Center

- .Ultrasonic and dry-blast mold cleaning

- .On-Site Materials Laboratory

- .Material Analysis FTIR

- .On-Site Rubber Mixing

- .Performing Operation

- .24" Piston Size Compression Moulding Machines

- .Automatic Vision System

- .Automated Inspection Equipments

- .Lathe-Cut

- .PTFE-Coated Equipments

- .Trimming and Cryogenic de-flashing Machines

- .Post-Curing Oven with monitoring and alam function